NITIGO

New Release, Nitigo Fuel Transfer Pump with Auto-Stop Sensor

New Release, Nitigo Fuel Transfer Pump with Auto-Stop Sensor

Couldn't load pickup availability

NTFPNTFPNTFPNTFPNTFPNTFPNTFPNTFPNTFNTFPNT

Introducing the New Release, Nitigo Fuel Transfer Pump with Auto-Stop Sensor! Say goodbye to messy fuel spills with its innovative Auto-Stop Sensor technology. Powered by USC-C, this compact yet powerful pump is perfect for transferring fuel with ease. Get yours now and experience effortless fuel transfer today!

Specifications

|

Mode |

Nitigo Fuel Transfer Pump |

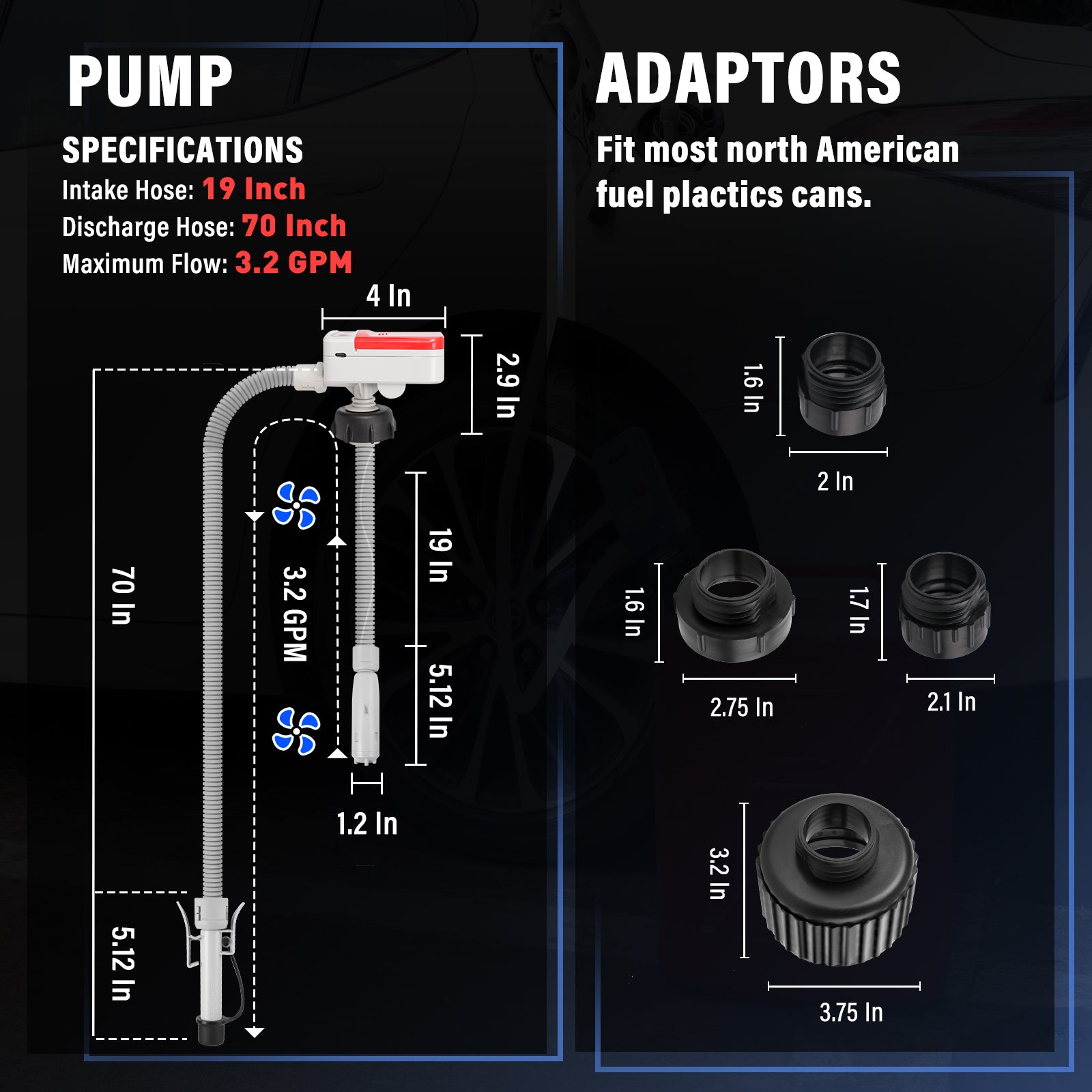

| Dimension | 70*4*19 inches |

| Weight | 2.05lbs |

| Charging Input | 12V |

| Power Source |

① USB-C cable ②4 x AA Battery (Not Included) |

| Material | ABS Plastic |

| Compatible With | Gasoline, Diesel, Kerosene, Water and a wide range of liquids( ☒hot water ☒corrosive substances) |

| Package |

1*Fuel Pump Transfer, 4* Can Adapter,1* Type-C Cable, 1* Storage Bag, 1*User Guide |

Share

Details

Details

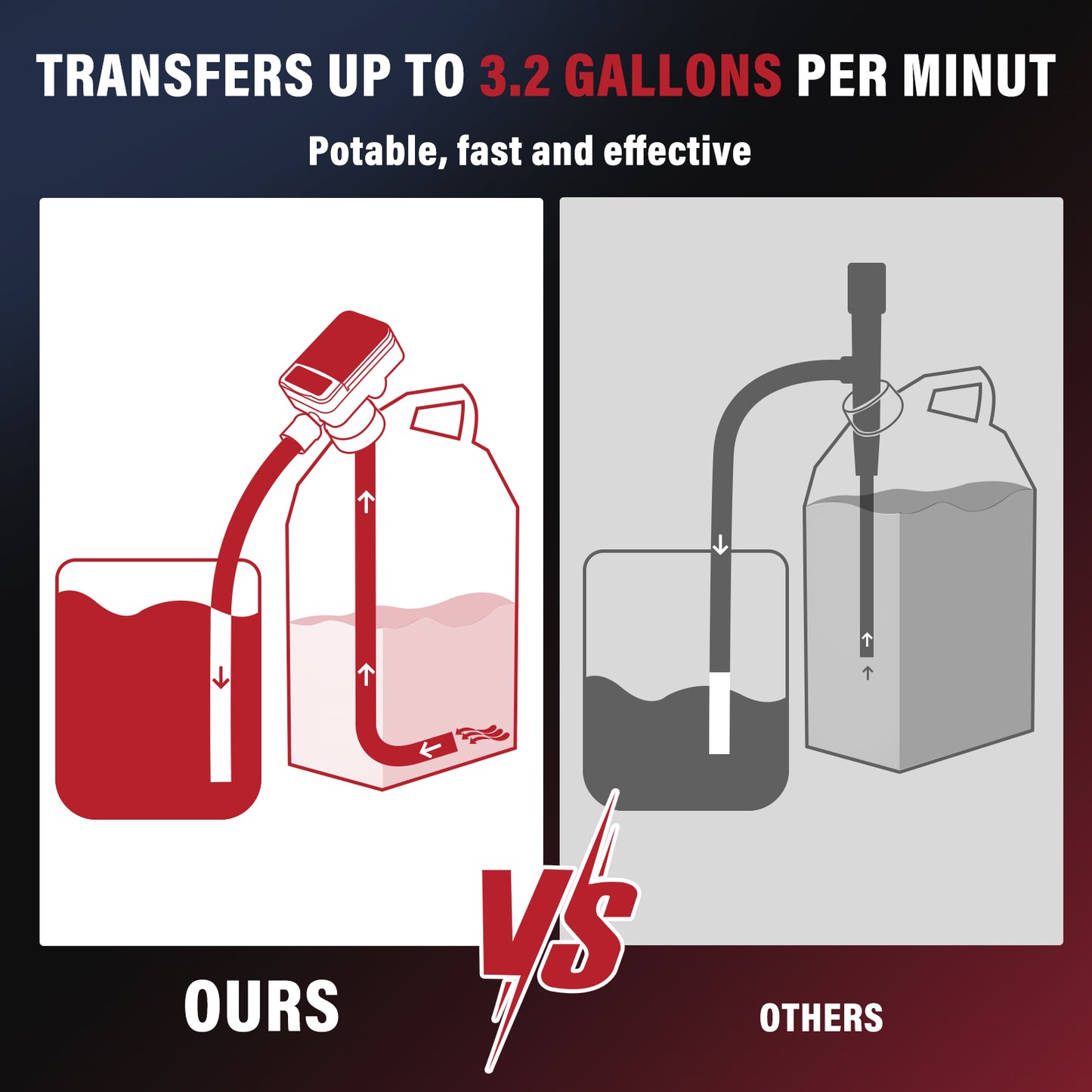

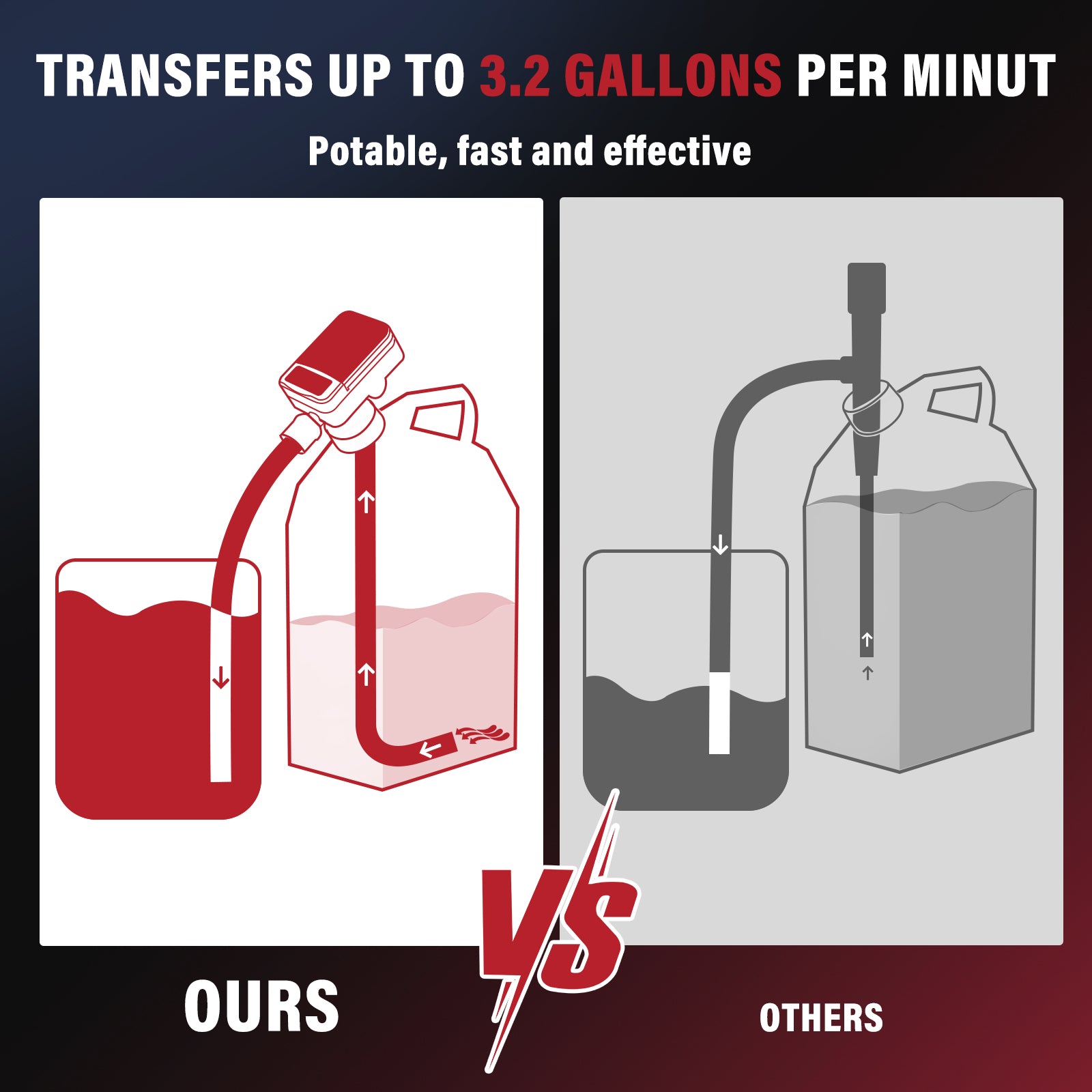

Delivery Volume: Pumping at a speedy 3.2 Gallons Per Minute (12 LPM), get ready for efficient fuel transfers.

Leak-Proof & Auto-Stop Design: Revolutionary 2024 model with a leak-proof design and an auto-stop system for hassle-free pumping. Crafted with a 70-inch hose made of durable polyethylene plastic, it resists rust and corrosion while being compatible with most North American cans. Equipped with four universal adapters (2", 2.1", 2.75", 3.75"), it offers unmatched versatility. Plus, with the built-in Auto-Stop feature, say goodbye to spills and mess, ensuring precision with every pump.

Versatile Applications: From gasoline and diesel to kerosene, light oils, non-potable water, and even urea, this pump is a versatile powerhouse.

Power Options: Choose your power adventure! It rocks on 4*AA Batteries (not included) Or Type-C On-the-Go

How To Use

How To Use

Warranty & Caution

Warranty & Caution

We stand by the quality and durability of our pump, providing you with a full year of worry-free operation.

1. No Fuel Transfer While Vehicle is ON: Turn off the vehicle and heater to prevent fire risks during fuel transfer.

2. Never Leave Pump Unattended: Avoid oversupply, fires, or accidents by monitoring the pump at all times.

3. Don't Alter or Disassemble: Ensure product integrity and safety by refraining from altering or disassembling the pump.

4. Keep Pump Away from Wet Areas: Prevent product failure by avoiding placement in wet areas.

5. Use Quality Fuels Only: Optimal performance requires high-quality, non-deteriorated fuels.

6. Avoid Hazardous Liquids: Protect the pump by refraining from using it with corrosive or hazardous substances.